Instrumentation systems monitor and control key process variables

like pressure, temperature, flow, and level within industrial facilities. Essential components include:

Function: Detect and transmit data on process parameters.

Examples: Pressure transmitters, temperature sensors (RTDs, thermocouples), flow transmitters (ultrasonic, magnetic), level sensors (radar, ultrasonic).

Function: Regulate fluid or gas flow within a process.

Examples: Globe, ball, butterfly valves; electric and pneumatic actuators.

Function: Automate control of industrial processes.

Examples: Allen-Bradley PLCs, Siemens S7 series PLCs.

Function: Centralize control for complex processes.

Examples: Honeywell Experion, Emerson DeltaV.

Function: Allow operators to interact with control systems.

Examples: Touchscreen panels, graphical displays.

Function: Measure the flow rate of liquids or gases.

Examples: Turbine, Coriolis, electromagnetic flow meters.

Function: Monitor and measure system pressure.

Examples: Bourdon tube gauges, diaphragm switches.

Function: Oversee and control plant processes.

Examples: SCADA systems, emergency shutdown (ESD), fire and gas detection systems.

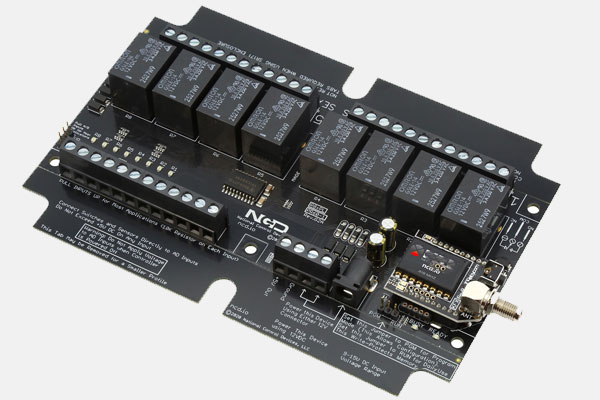

Function: Control processes and devices based on set conditions.

Examples: Time delay relays, safety relays, temperature controllers.

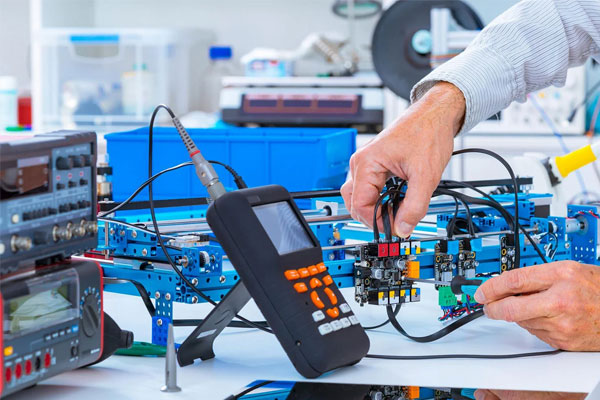

Function: Ensure instrument accuracy.

Examples: Pressure calibrators, loop calibrators, temperature baths.

Function: Monitor conditions in remote or hazardous areas.

Examples: Vibration sensors, humidity sensors, gas detectors.

Function: Convert or isolate signals to ensure compatibility with control systems.

Examples: 4-20 mA to 0-10 V converters, isolated signal amplifiers.