Mechanical Components

Bearings

Reduce friction between moving parts in machinery.

Types include ball bearings, roller bearings, and thrust bearings.

Gears

Transfer motion and torque between different machine parts.

Types include spur gears, bevel gears, and worm gears.

Couplings

Connect two shafts to transmit power while accommodating misalignment.

Types include rigid couplings, flexible couplings, and universal joints.

Fasteners

Essential for assembling machinery and structures, including bolts, screws, nuts, and washers.

Hydraulic and Pneumatic Components

Hydraulic Pumps

Convert mechanical energy into hydraulic energy to power systems.

Types include gear pumps, vane pumps, and piston pumps.

Valves

Control the flow and pressure of fluids in hydraulic and pneumatic systems.

Types include ball valves, check valves, and solenoid valves.

Cylinders

Convert hydraulic or pneumatic pressure into linear motion.

Types include double-acting cylinders and single-acting cylinders.

Electrical Components

Motors

Convert electrical energy into mechanical energy.

Types include AC motors, DC motors, and stepper motors.

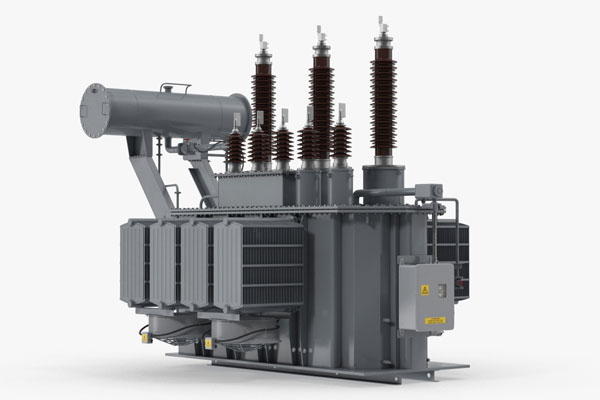

Transformers

Transfer electrical energy between circuits by stepping up or stepping down voltage.

Switches and Relays

Control the flow of electricity in circuits.

Types include toggle switches, push-button switches, and contact relays.

Circuit Breakers

Protect electrical circuits from overloads and short circuits.

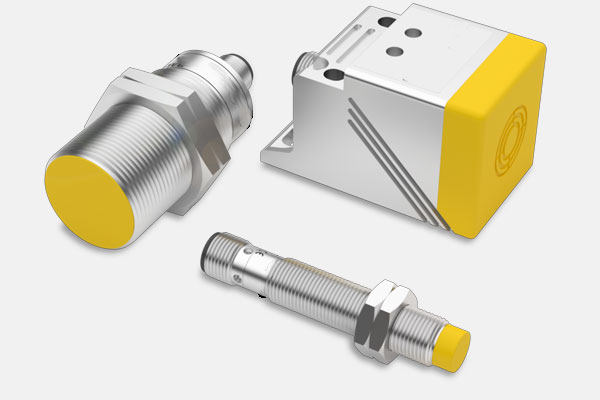

Instrumentation and Control Parts

Sensors

Detect physical properties such as temperature, pressure, and flow.

Types include temperature sensors, pressure sensors, and flow meters.

Controllers

Devices that regulate machinery operation based on sensor input.

Types include programmable logic controllers (PLCs) and distributed control systems (DCS).

Displays and Indicators

Provide visual feedback about system status and performance.

Types include digital displays, analog gauges, and LED indicators.

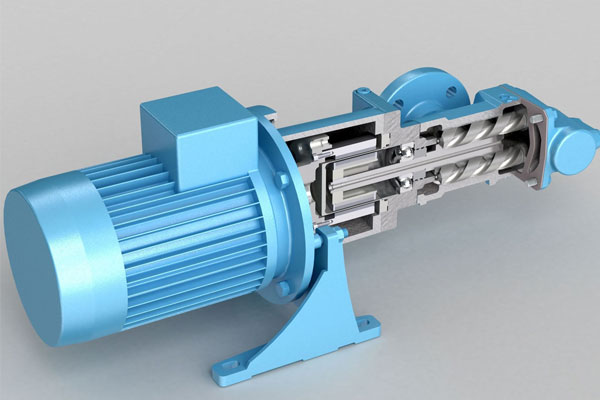

Industrial Pumps

Centrifugal Pumps

Move fluids by converting rotational kinetic energy into hydrodynamic energy.

Positive Displacement Pumps

Move fluids by trapping a fixed amount and forcing it through the discharge.

Diaphragm Pumps

Utilize a diaphragm to move fluids, making them suitable for corrosive or viscous liquids.

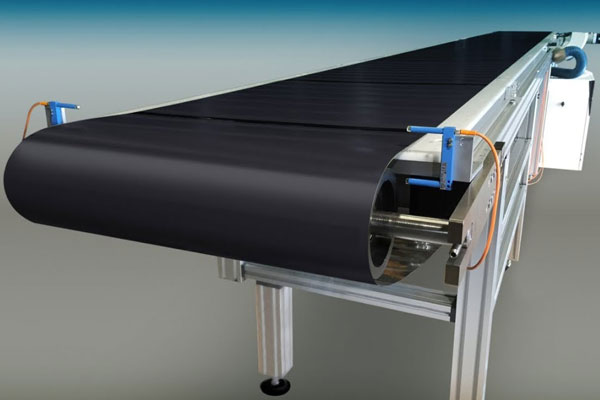

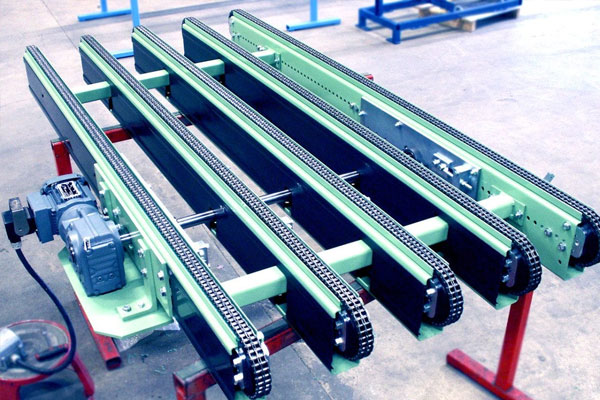

Conveyor Systems

Belt Conveyors

Transport materials from one location to another using a continuous belt.

Roller Conveyors

Utilize rollers to move items along a track, ideal for heavier loads.

Chain Conveyors

Employ chains to transport materials more robustly.

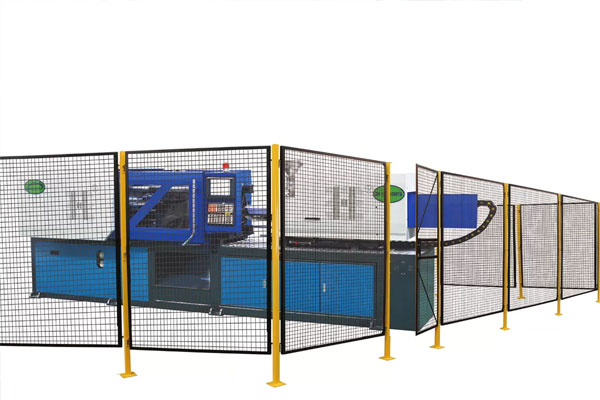

Safety Equipment

Guards and Shields

Protect workers from moving parts and hazardous areas.

Emergency Stop Buttons

Allow for quick machinery shutdown in emergencies.

Safety Sensors

Detect unsafe conditions and automatically stop machinery.

Maintenance and Repair Parts

Filters

Remove contaminants from fluids or air in industrial systems.

Seals and Gaskets

Prevent leaks in pipes, pumps, and other components.

Lubricants

Reduce friction between moving parts and extend machinery life.